I wood-fired 71 more vessels for the Each Day, Water project. Hopefully there will be some "keepers" for the exhibition.

In addition to my ongoing use of snowcap shino (which I layered very thick in some areas), I tried out some glazes new to these particular porcelain vessels: carbon trap shino, pearl shino, bopshin d, mamo white, and olsen shino. I can't wait to see what happened!

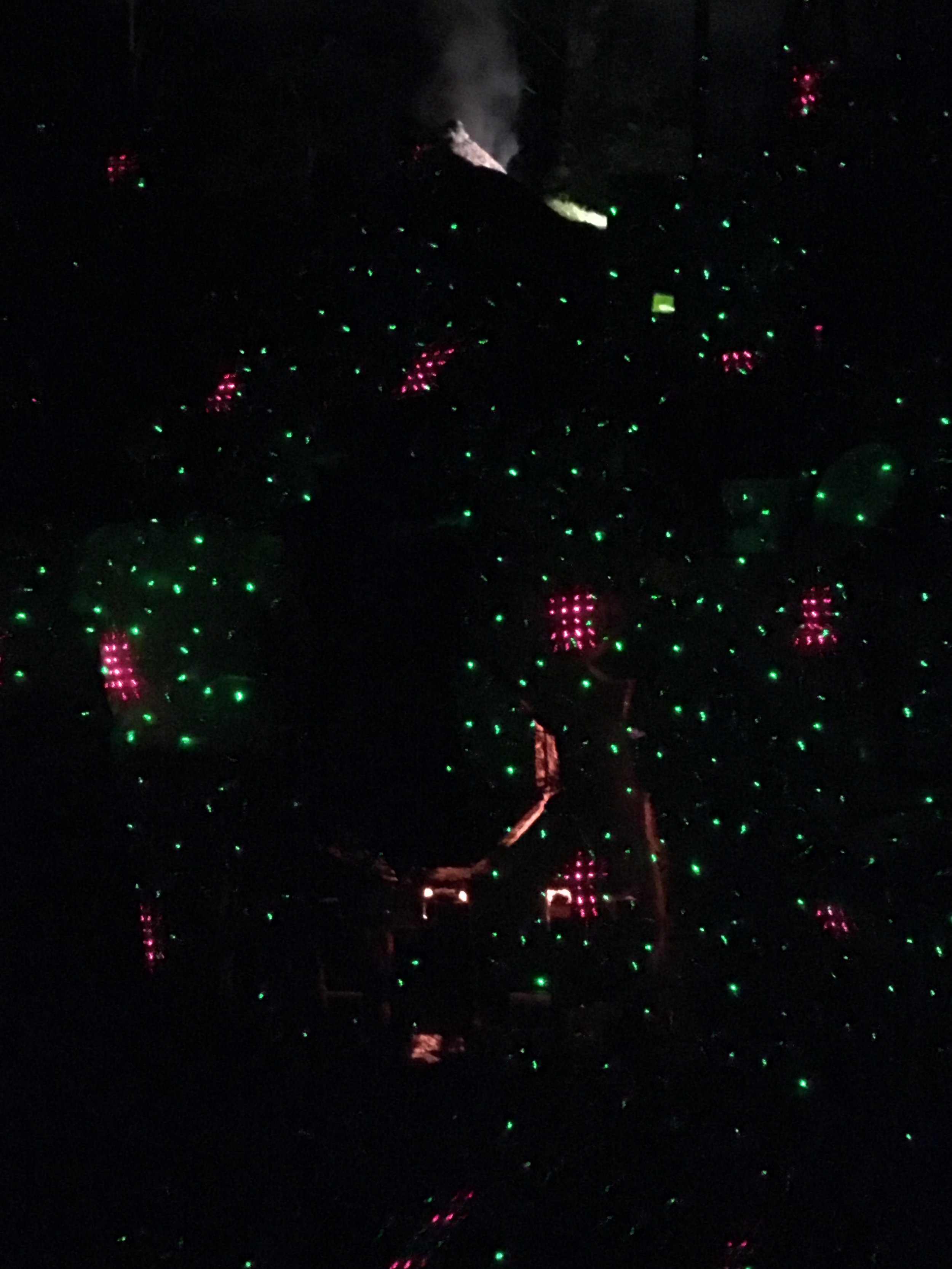

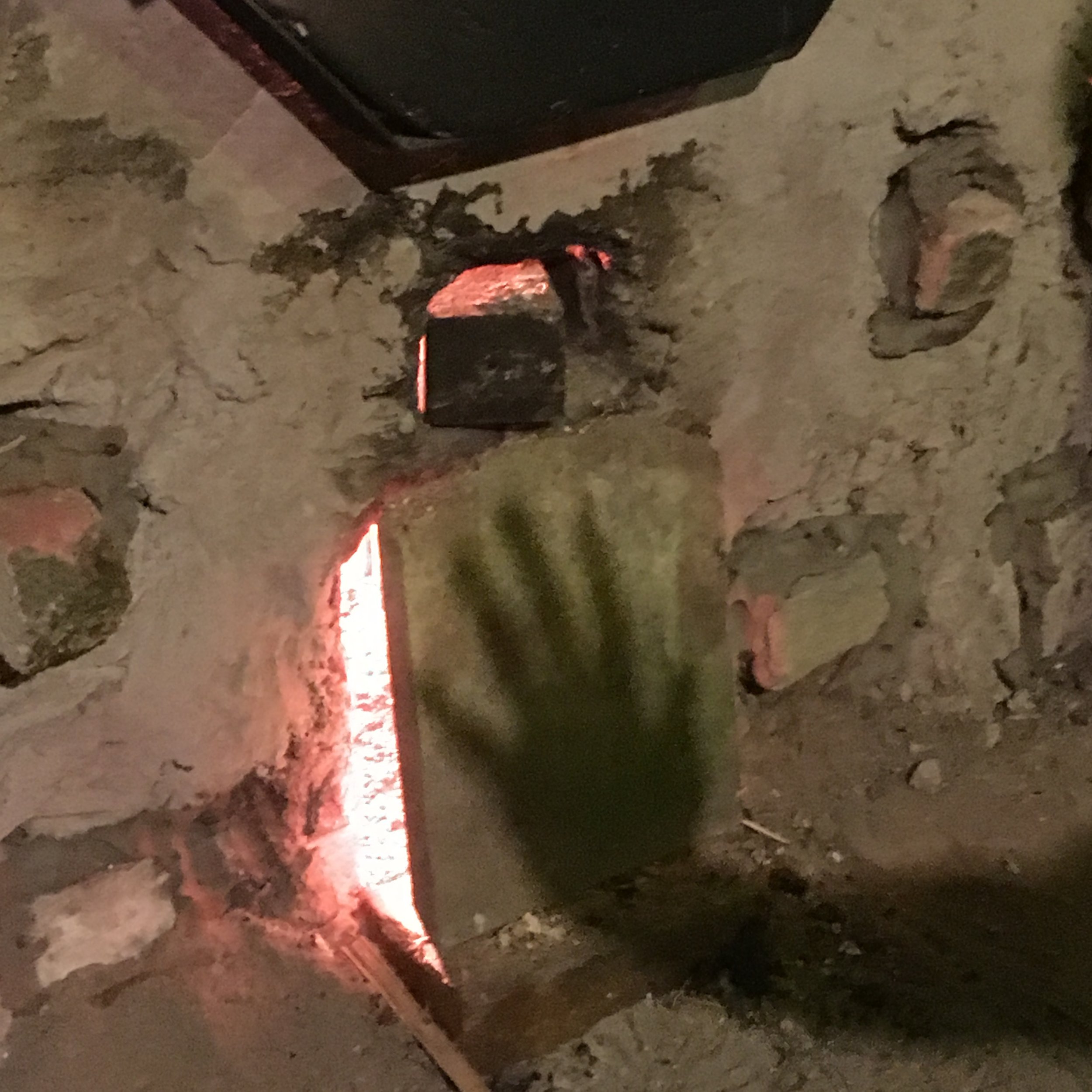

I stoked on the closing shift, 4 pm to midnight on Saturday, Dec 1. We definitely reached ^10 all around, and up to ^13 in the hot areas of the kiln. The air was cold on our backs, but the kiln kept us warm. The moon was full. At one point, after the closing began, green flames rose from the kiln's chimney-top. The moon, rainbow-orbed, wavered through the heat waves rising from the flames. It was really fun to close at Tony's kiln - stuffing cracks with K-wool and mudding over the portals and red-hot cracks. Steam coming off the trowels, the clay drying-on-contact. We enjoyed some wonderful vegetable miso soup, generously prepared by Tony's wife, at midnight when we were done. I tried to recreate it the next day in my own kitchen. Sadly, Olivia didn't like parsnips.

RESULTS:

Our unloading was postponed a day due to our first snowfall of the season. In terms of results, the vessels where I layered the snowcap shino thick in some areas over the former layer (which didn't have great melt in the summer firings) came out really WILD. The thicker glaze actually seems to have fallen off many of the pots, taking the prior layer with it, and leaving big swathes of naked clay beneath that flashed light peach (and accepted no ash). The thick snowcap shino also shivered a lot. Snowcap always shivers on bisqueware of this porcelain, but since these were "re-fires" I wasn't expecting so much shivering. The problem seems to have been the thickness of the glaze. Basically, this experiment had a very high fail rate. In some pieces, the glaze folded onto itself as it was melting. I did get some "happy accidents," particularly with drips and folds of thick glaze (that didn't shiver), and the cups where I added some Robinson's Blue and Olive Celadon into the mix were quite wild/lovely. But 41 cups was plenty for that experiment.... too many. I'll probably only keep about 10 of them for the show.

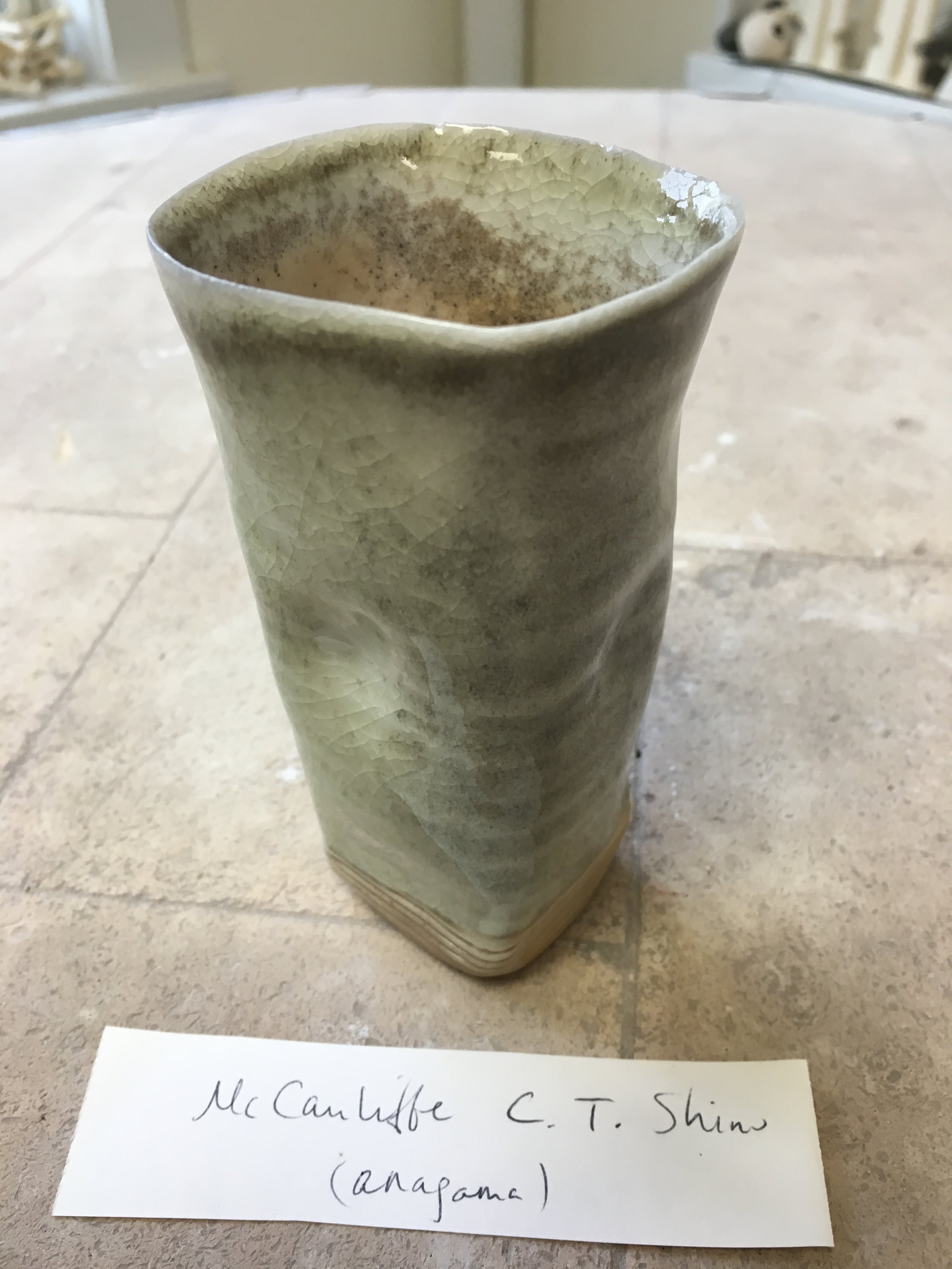

As typical for a wood-firing, "chance" ruled. In some areas of the kiln there was more carbon trapping than others, and ditto with the level of heat, heat work, and wood-ash. I also got some peach-colored flashing with glazes where I didn't expect that to happen at all. Most of my favorites came out of the anagama, but I got several lovelies from the noborigama, including a mamo white delicacy that turned a lovely shade of light yellow.

In general, these are my findings:

* Of the new glazes, the clear winner is carbon trap shino (it fired with a green-gray cast). Bopshin D takes second place. Though it flashed peach in some areas, for the most part this was subtle and beautiful. I'll use both these glazes again. The carbon trap shino crazed a lot, which might indicate a glaze fit issue with this clay body, I'm going to look into this.

* The pearl shino flashed too peach (for what I want for this project) in the wood kiln. It might work better in gas reduction firings to get the silvery-grays that attracted me to trying the recipe.

* I might try the olsen shino in the anagama next time; on my clay body it fires very deep brown in the noborigama (even though it is gray on the porcelain test tiles). Nevertheless, there was some gorgeous iridescence! Where the flame touched and/or it got super-hot in the noborigama, it did turn grey.

* The mamo white went a deep greyish purple in the anagama.